INDUSTRIAL WASHING SYSTEMS BUILT TO LAST

Engineered Washing Solutions for Every Industry

Girton engineers and manufactures high-performance industrial washing systems trusted across food processing, pharmaceutical production, laboratory research, and reusable packaging operations. Every machine is built for durability, precision cleaning, and long-term reliability

1 Know and meet your customers’ needs and help them achieve success.

2 To use the combined strength of our engineering, manufacturing and servicing skills to continually provide non-proprietary superior assistance and results to our customers

INDUSTRIES WE SERVE

Girton provides custom-engineered washing systems designed to meet the demanding needs of food processing, pharmaceutical, laboratory, and industrial operations.

Food Processing

Our commercial washing systems support food processors with durable, sanitary, high-capacity equipment engineered to meet industry standards and demanding needs.

Laboratory Research

We design reliable laboratory washing equipment that delivers consistent cleaning performance for research facilities, animal-care operations, and specialized scientific environments.

Pharmaceutical

Our pharmaceutical washing systems ensure precise, compliant, repeatable cleaning processes for sensitive production environments requiring validated performance and consistent sanitation results.

Reusable Packaging

Our case, tray, and pallet washers deliver thorough cleaning and sanitation for all types of reusable packaging, ensuring efficiency and compliance in demanding production environments.

Thermal Storage

Girton’s King Zeero Ice Builder Cabinets deliver reliable thermal storage using direct expansion refrigerants or flooded ammonia, with capacities from 500 to over 100,000 lbs.

our Capabilities

Girton Manufacturing designs and builds custom stainless-steel industrial washing systems for sanitation-critical environments. We engineer equipment for food processing, pharmaceutical, laboratory, beverage, and other facilities where reliable, validated cleaning is essential.

In-House Design & Engineering: Custom solutions developed by Girton’s own engineers.

Service & Installation by Girton: Our team handles setup, maintenance, and ongoing support.

Manufactured in Millville, PA: All fabrication, assembly, and testing performed on-site.

Trusted by Leading Industry Associations

Learn more about Girton’s stainless steel washers, custom-built equipment, industry applications, and what to expect when working with our team.

Girton provides stainless steel industrial washers for food and dairy processing, pharmaceutical manufacturing, laboratory research, reusable packaging facilities, and other regulated industries requiring high-performance cleaning and sanitation.

Yes. Girton specializes in custom-engineered washing systems, offering tailored solutions for washing totes, drums, pallets, bins, cages, glassware, IBCs, and specialty components based on your facility’s requirements.

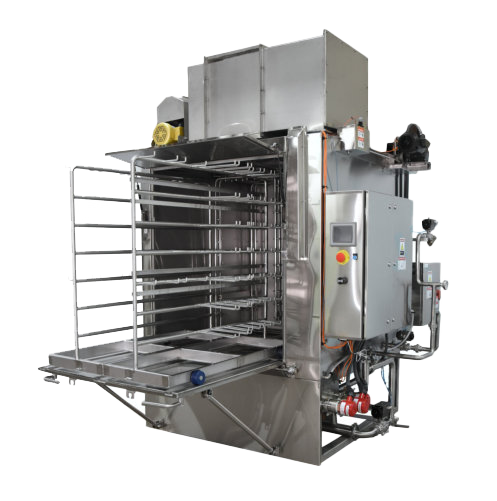

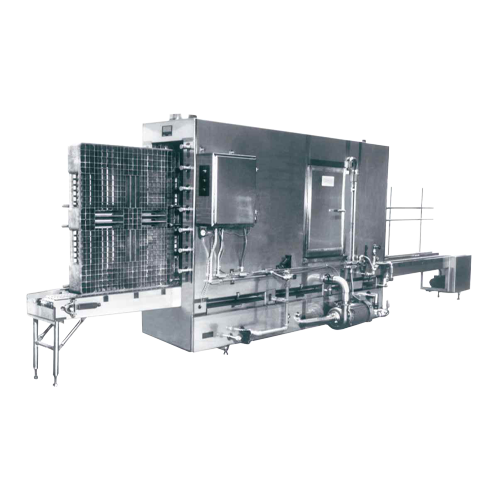

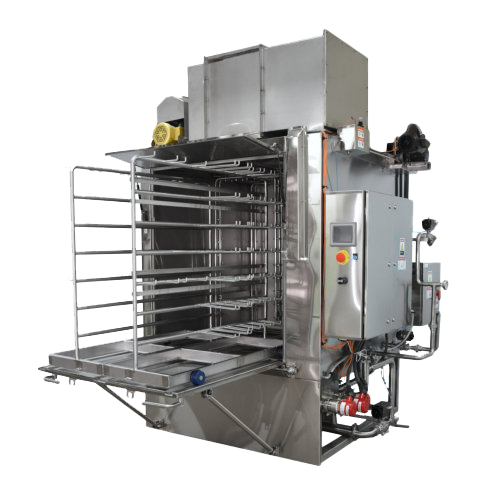

We produce cabinet washers, conveyorized and tunnel washers, custom-built systems, and thermal energy storage units. Each machine is made from heavy-duty stainless steel for long-term reliability.

Yes—every Girton system is engineered and manufactured in the United States, ensuring superior craftsmanship, quality materials, and dependable support.

Absolutely. Girton provides non-proprietary parts, ongoing maintenance assistance, and 24/7 technical support to keep your washing equipment operating at peak performance.

The King Zeero™ Ice Builder is one of the industry’s most efficient thermal energy storage systems, delivering consistent 34°F chilled water for cooling product lines and temperature-sensitive applications.

Speak with our team about custom stainless steel washers, equipment sizing, or project requirements. We’ll help you find the right solution for your facility.

Industry-Leading Industrial Washing Systems Engineered for Sanitation-Critical Environments

Girton Manufacturing designs and builds custom industrial washing systems for food processing, pharmaceutical production, laboratories, beverage plants, and other environments where sanitation and compliance are essential.

Our stainless-steel washers are engineered to deliver consistent, validated cleaning performance using controlled spray systems, programmable wash cycles, thermal disinfection, and automated rinse and sanitizing stages.

With more than a century of manufacturing expertise, Girton provides conveyorized washers, cabinet washers, pan and tray washers, tote and bin washers, CIP/COP systems, and fully customized wash lines. Every system is built to meet strict hygiene and regulatory requirements, including 3A Sanitary Standards, USDA guidelines, FDA expectations, HACCP programs, and GMP compliance.

Girton equipment is designed to remove allergens, residues, proteins, and microbial contaminants while optimizing water usage, energy efficiency, and operational throughput. Our advanced PLC and microprocessor controls ensure repeatable performance, seamless integration, and reliable operation in demanding production environments.

From concept to installation, Girton delivers engineered washing solutions tailored to the exact needs of your facility—helping you maintain the highest standards of cleanliness, safety, and productivity.