Engineered Washing Solutions for Food proCessing industry

Girton Manufacturing designs and builds food processing washing systems engineered for the strict sanitation needs of today’s food industry. Our stainless-steel equipment supports dairy, meat, beverage, bakery, and ready-to-eat operations with reliable, hygienic cleaning performance that meets USDA and 3-A standards.

Innovations That Helped Shape the Food Industry

For more than 80 years, Girton has developed advanced sanitation equipment that continues to set benchmarks for food industry cleaning. Our engineering team has delivered:

Stainless-steel washers manufactured to meet 3-A and USDA guidelines

A specialized soaker-type bottle washer for returnable 64 oz. and 2-liter glass bottles

Patented injector-type, full-flooded refrigeration systems for farm milk cooling tanks

OUR PRODUCTS

All equipment is designed, fabricated and tested in our facility located in Millville, PA before it is shipped

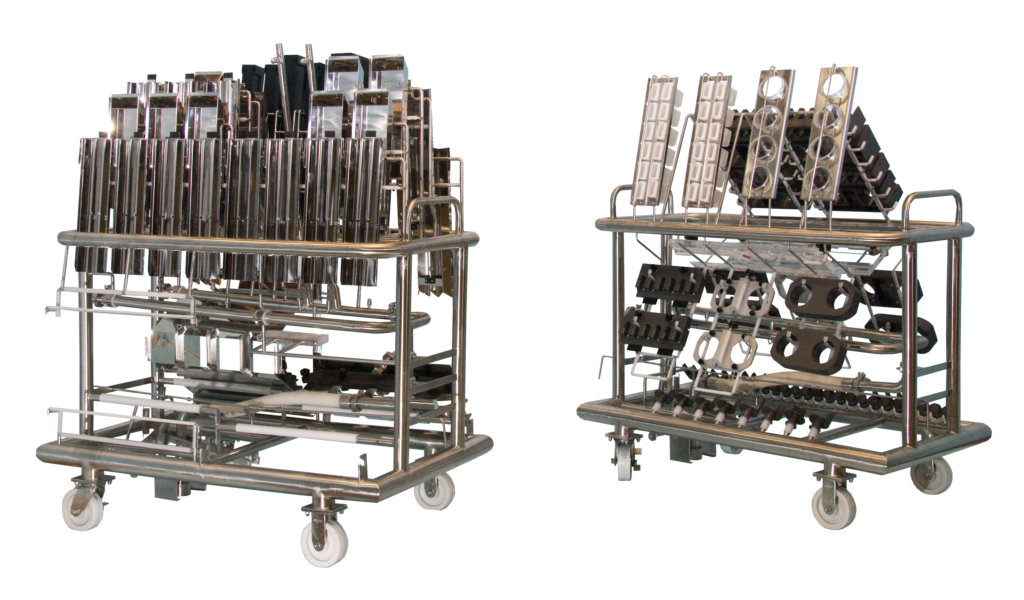

Girton Manufacturing Co., Inc. manufactures a broad line of stainless steel washing systems for the Food Industry. Our product line includes, but is not limited to, Conveyorized Tunnel, Cabinet, Case and Drum Washers as well as Indexing Bin and Tote Washing Systems; COP Tanks, Pallet Washers and Rotary Brush Washers.

Advanced solutions for a demanding world. After more than 80 years since Paul Girton founded the company, Girton still uses his same philosophy, “Service an industry by tailoring equipment to meet the specific customer’s needs”.

Speak with our team about custom stainless steel washers, equipment sizing, or project requirements. We’ll help you find the right solution for your facility.

Engineered for High Throughput & Long-Term Reliability

To keep production running smoothly, Girton washers are built for:

- Heavy-duty stainless steel construction

- Automated cycle controls for repeatability

- Efficient water use and heat recovery options

- High spray pressures for tough residue

- Adjustable cycle parameters for different soils

- Custom racks, carriers, and conveyors

- Serviceable, long-lasting components

From small batch operations to large-scale facilities, each system is engineered to maintain uptime and reduce labor.

Why Pharmaceutical Facilities Choose Girton

Girton washers are trusted by leaders across pharmaceutical manufacturing, biotech research, vaccine production, and sterile processing.

- Over 90 years of washing system engineering expertise

- All equipment built in-house in Millville, PA

- Systems supported by Girton’s own installation and service teams

- Proven track record in pharmaceutical, biotech, and sterile environments

- Durable construction designed for high-demand applications

- Ability to support both new and legacy cleaning processes